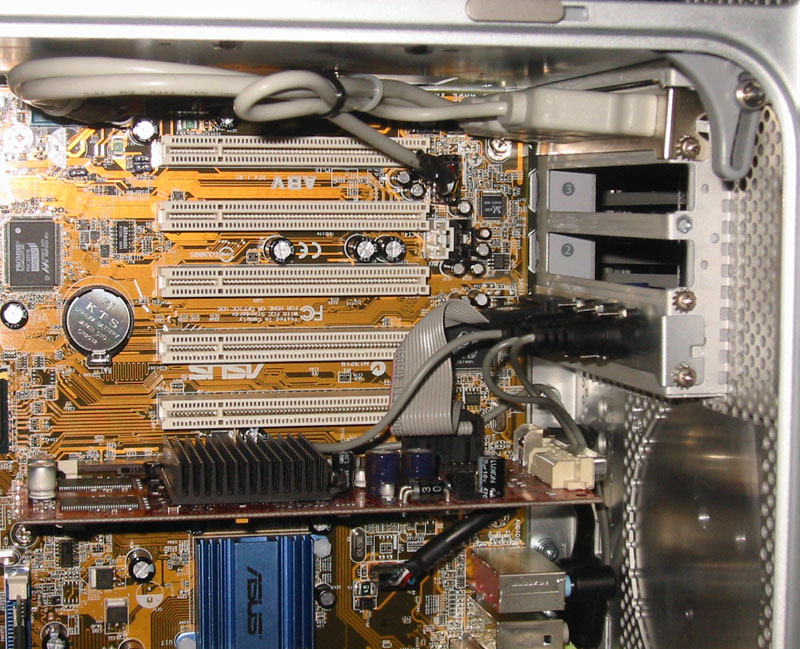

This documents the initial stage in my quest to build a completely fanless PC. An Asus A8V motherboard was chosen for this set-up due to minimal heat output, and under-volt and under-clocking capabilities in case my design proved inadequate.

A recycled G5 shell from eBay was chosen for two reasons: 1) It is large and full of holes to allow for the dissipation of heat; 2) It is a relatively simple and aesthetically pleasing design. I have no desire to pretend that this is a G5, or make some sort of “anti-Mac” political statement. I feel that it is the best looking case available at present, and it was a challenge to mod it for my purposes.

The large, external heatsink serves multiple purposes as well: 1) Its large mass cools hot components extremely well, although the heat-rise and cooling capacity were not calculated (I do tech, not physics…); 2) It covered up the unsightly fan brackets and cleaned up the back of the case quite nicely.

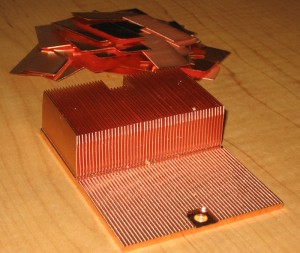

A copper Athlon 64 cooler was hacked apart and sanded down to make a suitable adapter for the heat-pipes. Additional copper and aluminum plates were fashioned out of scrap metal from eBay.

Using a drill-press, channels were made into copper and aluminum plates. These were attached to the processor using the stock AMD mounting screws. Blocks were attached to the large, external, aluminum heatsink via bolts screwed into tapped holes (many thanks to the local hardware store that helped me through that process!). The same bolt/thread pattern was used to mount the ~10lb. heatsink to the back of the G5 case. The hand-bent heat-pipes were scavenged from Thermaltake “Fanless VGA Coolers”, and Arctic Silver V was used at all metal contact points.

The wires extending out the back are all zip-tied to an adhesive patch/loop on the side of the main heatsink to keep them organized. They also serve to keep them from getting pulled loose when I am rummaging around behind my desk. The power cord simply snakes through a slot I cut out of the heatsink early on in the project when I thought that most of the wires would exit the case that way.

Front Panel: The G5 font-panel I/O board was used so I could take advantage of the front USB, Firewire, and audio connectors, but a custom harness needed to be made. Through a bit of trial-and-error I discovered that the ribbon cable for a Dell Optiplex front panel fit the size of the pin-outs perfectly (considerably smaller than standard IDE cables). Using a multimeter and spare cables, I mapped the pin-outs, and kluged together the adapters necessary to attach them to my motherboard. Two of the three wires from the power switch were also isolated (after a bit of trial-and-error… notice a pattern here…). I could not figure out how to power the stock power/standby light, so two new LEDs were added as well.

Rear audio/video: Using components obtained from FrontX (they have a lot of cool stuff and FAST shipping… although it all is a bit pricey) I made connections for headphone-out, line-in, RCA-out, and composite video-out.

Video card: This particular implementation of the Radeon 9600 card was chosen because it has a modular VGA connector on a short ribbon cable. With a swap of the PCI bracket the card can be used in a low-profile case with DVI and composite-video-out remaining intact (this is what was done with a similar card in my low-profile Netvista case). This setup allows for easy routing to a blank PCI slot-cover that was modified with my trusty Dremel tool. It also provides clean routing of wires since my composite video/RCA cable is a three-in-one design that wraps around the living room to the old-school TV. It would have been easier to use a micro-ATX motherboard that would have ultimately placed the video card higher in the case, but I would have lost the ability to overclock and undervolt the processor. You may also be wondering why I didn’t just use a PCI video card, or buy a motherboard that had both PCI-express and AGP (with the AGP slot aligned with an intact case opening)… The answer is simple: I wanted a relatively fast card, and was concerned that it may overheat in a completely fanless case. While building aluminum/copper blocks to connect the processor’s heat-pipes to the external heatsink, I also made a block for both the video card and the motherboard chipset. If you look closely, you can even see the holes tapped into the back-side of the external heatsink at a level slightly above the video card. While torture-testing the rig I noticed no instability in the video card or chipset, so it seemed like overkill to add the additional heat-pipes at present (I have way too many projects as it is…).

Hotkeys and eject button: Since ATI cards do not play DivX movies on the display and TV screen simultaneously I mapped some hotkeys to change the primary display quickly (with no silly “are you sure you want to do this?” prompts). Since an eject button is absent from the front I added an “eject” key that is mapped to a simple utility called WinEject. It only works when windows is loaded, but if I need to access the drive in DOS I can simply slide the G5 drive-door down with a finger and hit the button on the DVD-R itself… no big deal.

The 1.8Ghz Athlon processor has been very stable with 1gig of Kingston ValueRam, and easily overclocked to 2.1Ghz on 1.35 volts of power (try that with a P4!). The multiplier does not go above 9X, so this mild overclock was done by setting the FSB at 233Mhz with the AGP and PCI buses locked. The hypertransport bus was set at 4/5s to keep it within spec (final memory speed is ~933Mhz), and there is still room to tweak it a bit more when time allows. With “CPU burn-in” the temperature stabilizes around 51°C within 45 minutes, and it usually hovers at about 37°C with a case temp of 34°C at idle. This configuration has been running without a hiccup for two months at press time. The cooling blocks have been drilled to accept an additional heat-pipe if necessary, and I am looking forward to testing the heat-dissipation limits of this system.

In the interest of full disclosure… I am not a gamer, so it is possible that the video card could overheat with a “real” stress-test. I will test it with a game demo when time allows.

Upon reflection, playing a DVD while simultaneously compressing offline video is probably the most demanding thing I do with this rig (it is why I even bothered to upgrade from a 1.0Ghz PIII). It is not uncommon for me to have a cue of compression jobs keeping the CPU load near 100% for 12-24 hours at a time, and it must be stable enough to serve as an entertainment center simultaneously. Although extended video compression jobs don’t bring processor temps as high as synthetic tests (2-3°C lower than CPU burn-in with this cooling system), the additional heat/power-draw from the video card and hard drive cranking away is about as much abuse as I can possibly muster.

The Seagate Barracuda V hard drive is mounted in a Zalman heat-pipe cooling adapter that does not completely dampen the seek noise. This is adequate for now, but will need to be silenced a bit more in the next round of mods since I tend to leave the side of the case off. The power supply fan is very quiet, but still audible. A fanless version will be added when funds allow, and will likely work just fine since the current unit does not vent outside the case as-is. As an added benefit, a newer-generation power supply would also provide a 10-15% increase in efficiency and further reduce the system’s overall heat production.

When it comes down to it… cooling the processor without a fan was the primary goal/challenge of this project. The next round of upgrades requires more spending than hacking… what fun is that? Hope you enjoyed the show so far.