A fun project that I have been working on for a few years is my CNC machine. A lot can be learned through trial and error, but progress was slow for quite a while. To jump-start the process, I ended up using a fairly basic kit from eBay. Actually, it is two kits… one for the frame, and one for the Gecko drive components.

Here is an initial shot of the machine:

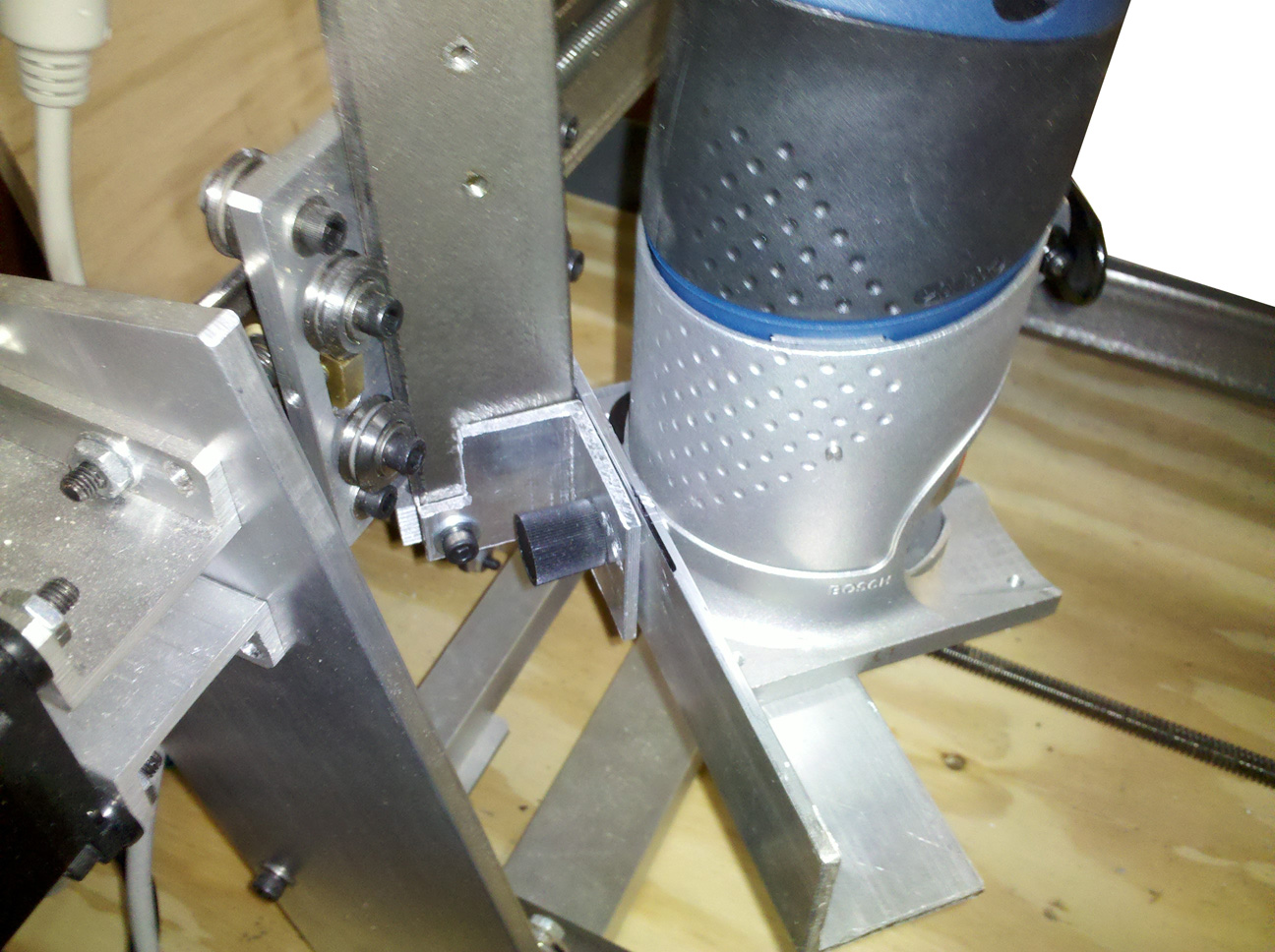

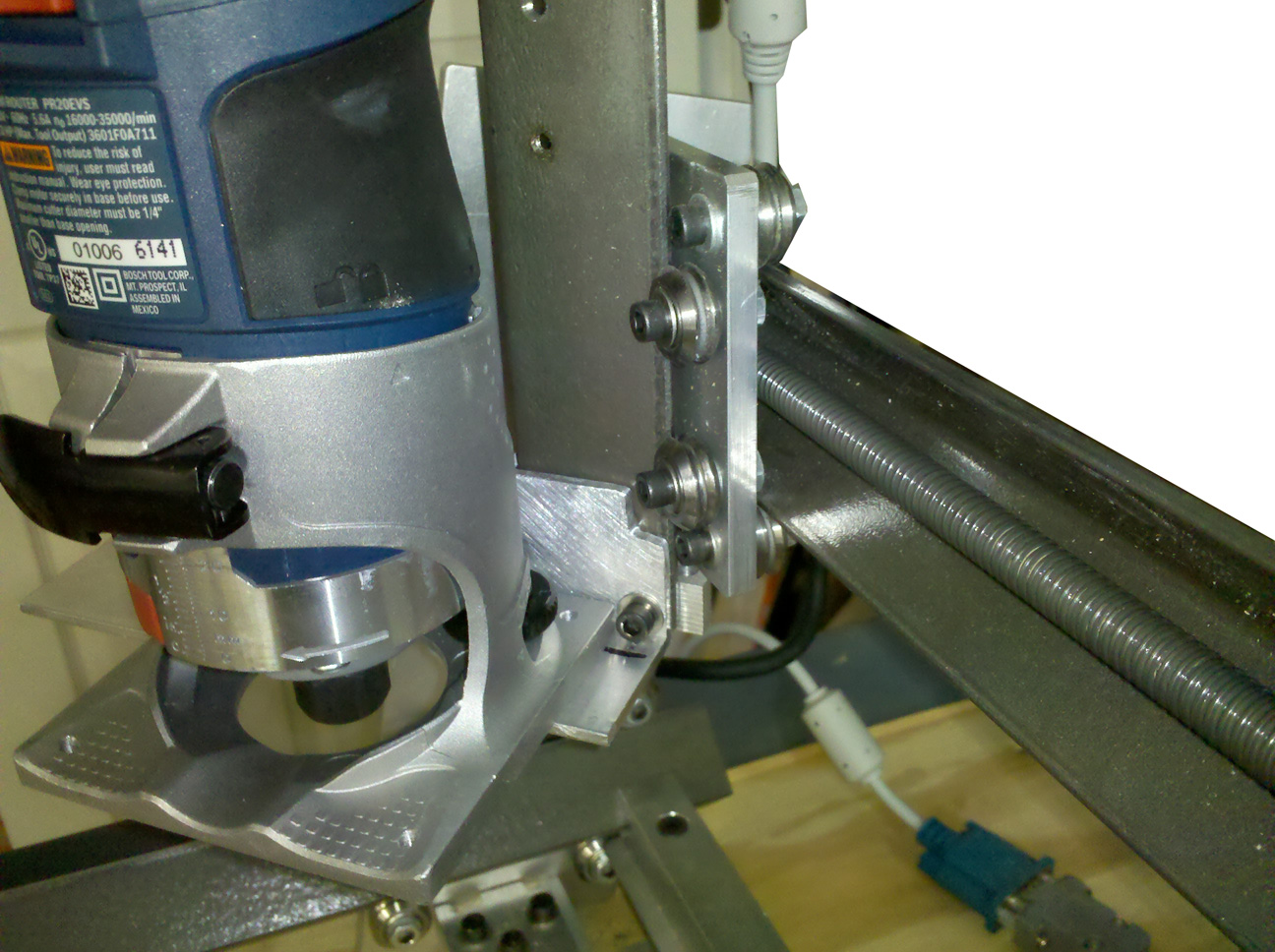

The first step was to construct a mount for my router. I used 1/8″ aluminum angle stock and attached it to the stock Bosch base for the palm router. I like the router so much that I bought a second router base to use the router off the CNC machine as well.

A “dust boot” was then added from a door sweep. this worked very well to contain dust, but had to be removed in the end since it interfered with cutting. The bristles were too stiff, and it caused a minor amount of deflection in the mount while routing. My goal in the end is to put this into an enclosure, so the boot is not particularly essential.

The critical part is the vacuum mount. The parts were salvaged from a broken upright machine, and silicone caulking holds the plastic in place. It is nice to be able to remove the hose when necessary. Without the dust boot the vacuum picks up most of the debris, but I am still looking for a better solution.

Clamps were purchased from Rockler (one can be seen in the shot above), and they are pretty nice. However, when cutting out small designs, they got in the way. So… I designed some low-profile clamps using bolts and plywood strips. Two screws protrude a bit from each piece to “bite” into the wood being clamped down. The process leaves a few very small scars on the sides, but is very effective. Most importantly, the machine mount does not hit the clamps while cutting!

A t-slot cutting bit was used to make the channels for the bolts. It works well enough for now.